Stainless Steel Fasteners

Stainless steel fasteners are characterised by their durability and resistance to corrosion. This is because stainless steel is an alloy of iron with carbon, chromium and other elements, which give it an anti-corrosive property and a high resistance to oxidation. This material is especially suitable for applications exposed to humid or corrosive environments.

In CHAVESBAO we have more than 3.400 references in stainless bolts, stainless washers, stainless nuts, stainless rods and stainless cable and chain accessories, among other items.

Advantages of Stainless Steel Fasteners

High corrosion resistance

High durability

Ability to withstand adverse weather conditions

Higher level of hygiene in fasteners

Tolerance of extreme temperatures

Optimum torque retention

Low maintenance

100% recyclable

Stainless Steel Range

Stainless Steel Screws

Stainless steel screws are essential fastening elements due to their strength and durability. Stainless steel screws are resistant to humidity and extreme temperatures, making them ideal for applications in maritime environments, the food industry and the automotive industry, among others.

At CHAVESBAO we have hexagonal, allen, metal thread, car body, round head, sheet metal thread and self-drilling screws in A2 (AISI 304) and A4 (AISI 316) stainless steel.

Stainless Steel Nuts

Stainless steel nuts are used for fastening and fixing joints that require a high resistance to corrosion. Nuts made of stainless steel are used in applications exposed to humid environments or extreme temperatures.

At CHAVESBAO we have hexagonal, self-locking, square, blind and butterfly nuts in A2 (AISI 304) and A4 (AISI 316) stainless steel.

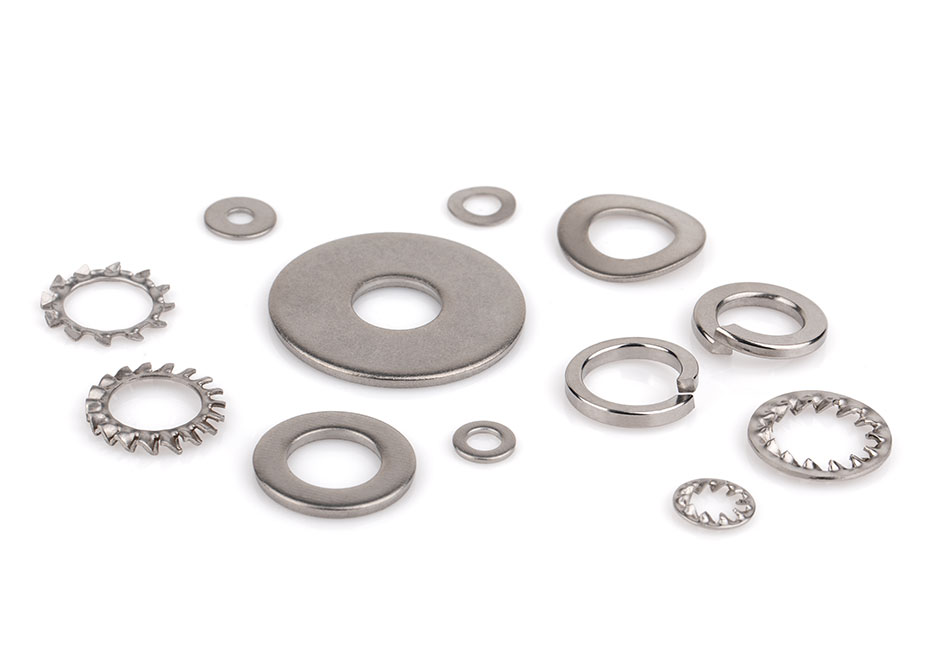

Stainless Steel Washers

Stainless steel washers are used to protect the fixing parts when greater durability is required in outdoor installations or damp environments. Washers made of stainless steel are recommended for use in the naval, food or automotive industries.

In CHAVESBAO we have flat, grower and toothed washers in stainless steel in A2 (AISI 304) and A4 (AISI 316) stainless steel.

Stainless Cable and Chain Fittings

Stainless steel cable and chain accessories are used to fix and protect cables and chains that are exposed to adverse weather conditions where other materials may rust.

At CHAVESBAO we have a range of eyebolts, cable clamps, shackles, turnbuckles, thimbles and carabiners in A2 (AISI 304) and A4 (AISI 316) stainless steel.

Other Stainless Steel Products

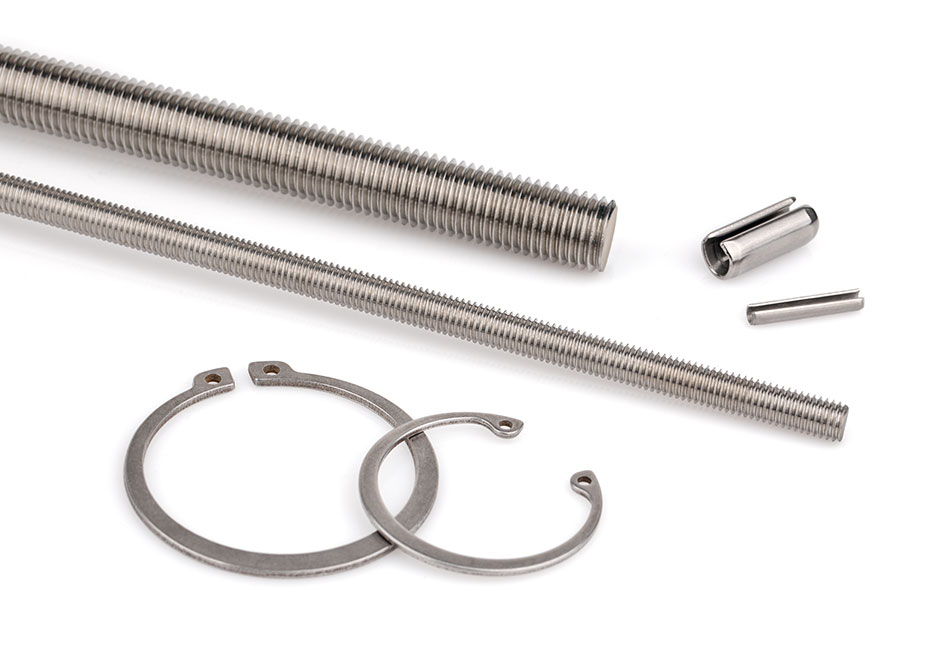

We have stainless steel threaded rods, as well as pins and rings also manufactured in stainless steel.

FAQS

Which screws are stainless?

Stainless screws are those made of stainless steel, which is an alloy of iron and chromium. There are different types of stainless steel depending on the percentage of chromium and the other elements they contain, such as nickel or molybdenum. The most common stainless steel bolts are A2 and A4, but there are also others according to the AISI (American Iron and Steel Institute) standard classification.

Why choose a stainless steel screw?

It is necessary to choose stainless steel screws when the fastening is exposed to adverse weather conditions, high temperatures or humid environments over time. An example of this type of fastenings are the marine walkways or the machinery used in the food industry.

Stainless steel is a material that guarantees durability and corrosion resistance, making it the ideal solution in harsh environments. Thanks to this resistance to corrosion, the structural, aesthetic and hygienic integrity of the stainless screws is maintained, avoiding signs of wear throughout their useful life.

What are the differences between A2 and A4 stainless steel?

A2 and A4 stainless steel are two types of steel with different properties, applications and characteristics. The main difference lies in the mechanical and corrosion resistance levels of each of them.

Depending on the specifications and requirements of each application, one of these stainless steels will be selected to guarantee a good performance and a long service life of the installation, especially outdoors or indoors with environmental condensation.

A2 is suitable for indoor spaces with high condensation frequency and high contamination from production processes. Outdoors it is used in temperate atmospheric environments with high pollution or chloride substance effect. Also in tropical or subtropical areas with low atmospheric pollution.

A4 is a stainless steel more suitable for applications in humid and aggressive environments. Indoors it is suitable for spaces with very high condensation frequency or production contamination. Outdoors it is used in temperate and subtropical areas with atmospheric environment with very high pollution or significant chloride effect.

What are stainless steel screws used for?

Stainless steel screws are metal parts that are used to join or fix different materials, such as wood, metal, plastic, etc. Stainless steel screws are characterised by their resistance to corrosion, oxidation, wear and tear and high temperatures. Stainless steel screws are used in different industries, such as automotive, aeronautics, naval, food, pharmaceutical, chemical and construction.

How to know if a screw is made of stainless steel?

The appearance of stainless steel is shiny and silvery. In addition, being a material that presents greater hardness and resistance, it does not bend or scratch easily.

It is also possible to know if a screw is of stainless steel through the magnetisation. Iron is magnetic, but stainless steel alloys are not, so if when you bring a magnet close to the screw it does not stick, it is probably stainless steel. Note, however, that stainless steel alloys with nickel can be slightly magnetic.

What is the difference between steel and stainless steel?

Steel and stainless steel are two types of metals that are identical in that they both have iron and carbon as their basic ingredients. However, they differ in the alloy content, as stainless steel contains at least 10.5% chromium, while carbon steel has an alloy of less than 10.5%.

It is this chromium layer that protects stainless steel from corrosion and oxidation. Carbon steel does not have it and can therefore rust easily.