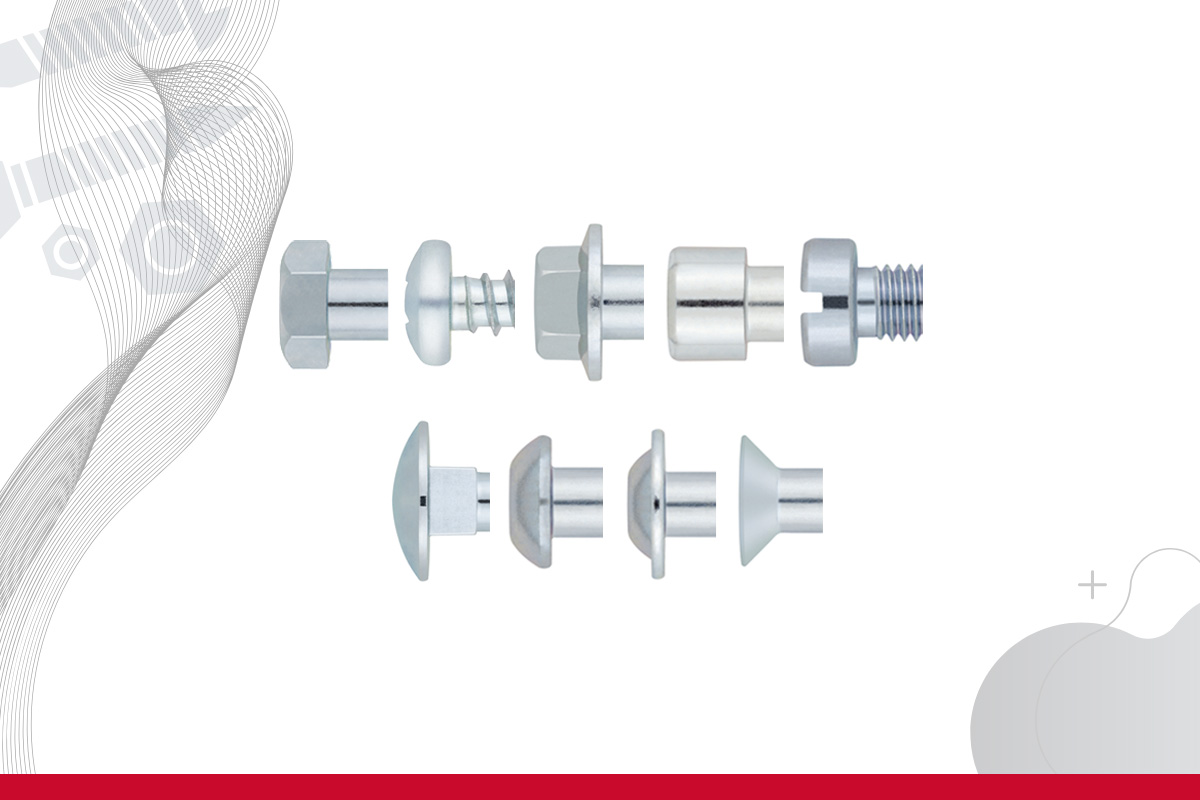

The points of a screw play a fundamental role in fastening, as they determine its ability to drill and anchor into different materials. Knowing the different types of points and their applications will allow you to choose the right screw for every need, optimising the strength and durability of the fastener.

In this guide, we will explore the main types of screw points, their recommended use depending on the material and key tips for their selection.

Types of screw points and their characteristics

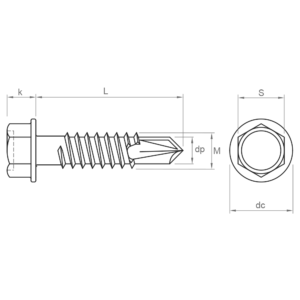

1. Drill bit point

- Description: designed for direct drilling of metal materials.

- Uses: ideal for metal-to-metal or wood-to-metal joints.

- Advantages: Saves time as no pre-drilling is required.

- Disadvantages: can wear out quickly in very hard materials.

2. Reduced drill point

- Description: variant of the drill point with a smaller initial drilling diameter.

- Uses: suitable for thin metal or wood materials.

- Advantages: creates a virtual nut in the material, achieving greater fixation.

- Disadvantages: reduced drilling capacity in thick materials.

3. S-type point (pin)

- Description: special head with 20-30º angle to penetrate soft materials.

- Uses: plasterboard, plastics, wood and thin metals.

- Advantages: Promotes insertion without damaging the material.

- Disadvantages: not suitable for hard or thick materials.

4. Point type C

- Description: 45º angled point requiring pre-drilling.

- Uses: fastenings in metal joints.

- Advantages: high strength and firm fixing.

- Disadvantages: drilling required prior to screwing.

5. Point type F

- Description: flat face and fine thread, designed for hard metals from 1.2 to 5 mm thick.

- Uses: metal-to-metal, plastics, impregnated wood and combinations of asbestos and other materials.

- Advantages: high strength in high density materials.

- Disadvantages: requires pre-drilling.

6. Diamond point

- Description: sharp point with triangular faces and 45º angle.

- Uses: concrete.

- Advantages: high penetration capacity in solid substrates.

- Disadvantages: requires suitable tools for installation.

7. Guide point

- Description: Round shape for easy insertion into pre-drilled holes.

- Uses: Ideal for automatic machinery and metal fasteners.

- Advantages: Prevents damage to threads and allows precise screwing.

- Disadvantages: not suitable for direct drilling without pre-drilling.

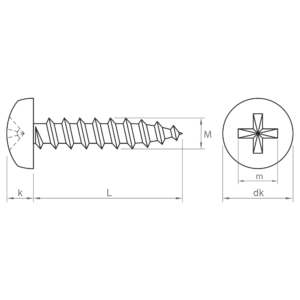

8. 2-wing drill point

- Description: includes two flanges for larger drilling diameters in wood.

- Uses: wood-to-metal applications.

- Advantages: reduces heating and prevents material breakage.

- Disadvantages: not recommended for thick metals.

9. Harpoon point

- Description: oval shape for easy insertion into plastic plugs.

- Uses: applications in fasteners with nailable studs.

- Advantages: high gripping capacity on soft materials.

- Disadvantages: not suitable for metal or hard materials.

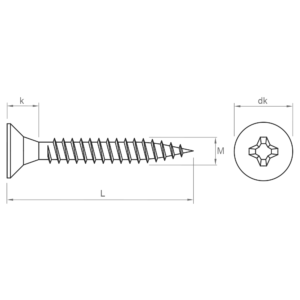

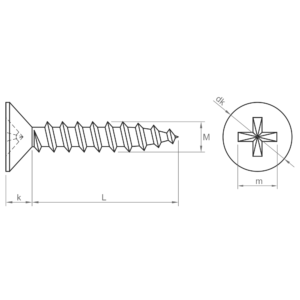

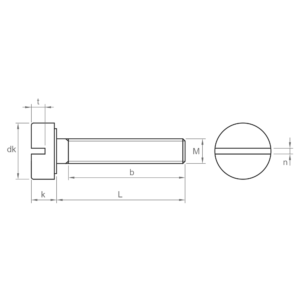

10. Flat point

- Description: with a straight edge at the end and no specific design.

- Uses: applications where a hole has already been drilled or in soft materials.

- Advantages: easy insertion into pre-drilled materials and less wear on screwdriving tools.

- Disadvantages: not suitable for metallic or hard materials.

How to choose the right screw point according to material

To ensure efficient fastening, it is important to consider the type of screw recess together with the appropriate point for each material.

MATERIAL | RECOMMENDED POINT | MAIN BENEFIT |

Wood | 2-wing bit point | Prevents overheating and cracking |

Metal | Drill point, type F | High strength and strong hold |

Plastic | Harpoon point | Better grip on nailable dowels |

Construction | Diamond point | Increased penetration into concrete |

Tips for selecting the best point

- Evaluate the material: not all points work well on all substrates.

- Consider the desired strength: tough materials require specialised points.

- Avoid overheating: some points generate high friction and can be damaged.

- Ensure proper installation: use proper tools to avoid deformation of the point.

Selecting the right screw point is crucial to ensure efficient and long-lasting fastening. At CHAVESBAO, we offer a wide variety of screws for different industrial and construction applications. If you need advice, contact us at info@chavesbao.com or visit our catalogue.