These two socket screws are an essential fastening element in many industrial applications. Here, we will focus on the DIN 913 and DIN 916 types, two of the most commonly used on the market.

Unlike DIN 912, DIN 913 and DIN 916 are headless and fully threaded, making them an ideal solution for internal connections or where a more secure and precise fastening is required to retain components.

As with all socket screws, their hexagonal interior makes them easy to install with the Allen key, so they are common in small or hard-to-reach areas. In addition, as they have no head, they are flush with the surface to obtain an aesthetic finish.

Types of socket screws DIN 913 and DIN 916

The socket screws are classified according to their mechanical resistance and the type of coating. At CHAVESBAO, we offer the following stainless steel options:

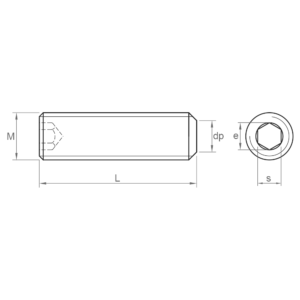

- DIN 913 A2: this flat tip socket screw is made of A2 stainless steel, so it is highly resistant to corrosion, being very suitable for humid or aggressive environments. It is similar to ISO 4026.

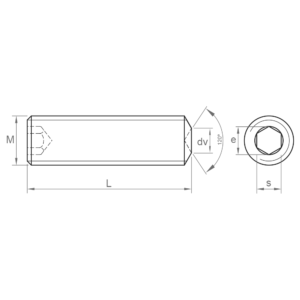

- DIN 916 A2: with full thread cylindrical design, without head and ring-ended tip, it is made of A2 stainless steel. It has a higher resistance to corrosion and is commonly used in environments with adverse weather conditions. It is similar to ISO 4029.

Features of DIN 913 and DIN 916

- Metric thread: allows secure and versatile fastening in a wide range of materials.

- Different lengths: available in a variety of lengths to suit different material thicknesses.

- High mechanical strength: A2 grade offers excellent tensile and shear strength.

- Easy installation: used with an Allen key, making them easy to install in tight spaces.

DIN 913 and DIN 916 applications

DIN 913 and DIN 916 socket screws are used in a wide range of industries:

- Industry: fastening of components in machinery, industrial equipment and metal structures.

- Automotive: fastening of components in chassis, engines and suspension systems.

- Construction: fastening of metal elements in structures and buildings.

- Furniture: joining of metal components in furniture and structures.

- Electronics: fastening of components on boards and housings.

What is the difference between DIN 913 and DIN 916?

Although they are both socket screws, there is one significant difference between the two: the design of the tip. While the DIN 913 socket screw has a flat tip, the DIN 916 has a ring-shaped tip. The decision to choose one or the other depends on the specific details of your project.