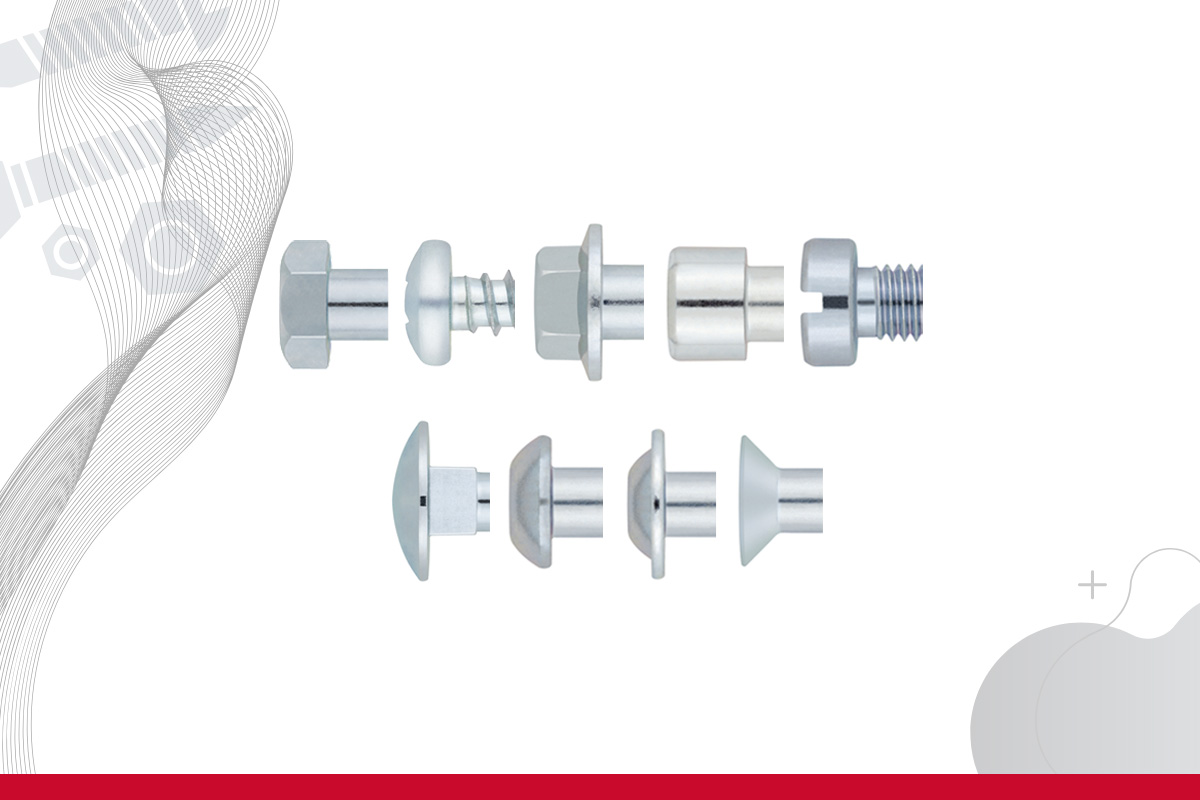

The screw recess is the cavity in its head that allows adjustment with a tightening tool. Choosing the right recess is key to ensuring efficient assembly, preventing premature wear, and improving the security of the fastening. In this article, we will explore the different types of screw drives, their applications, and how to select the most suitable one for each need.

Most common types of screw recesses

There are many types of recesses, each with specific characteristics and applications. Below, we describe the most common ones:

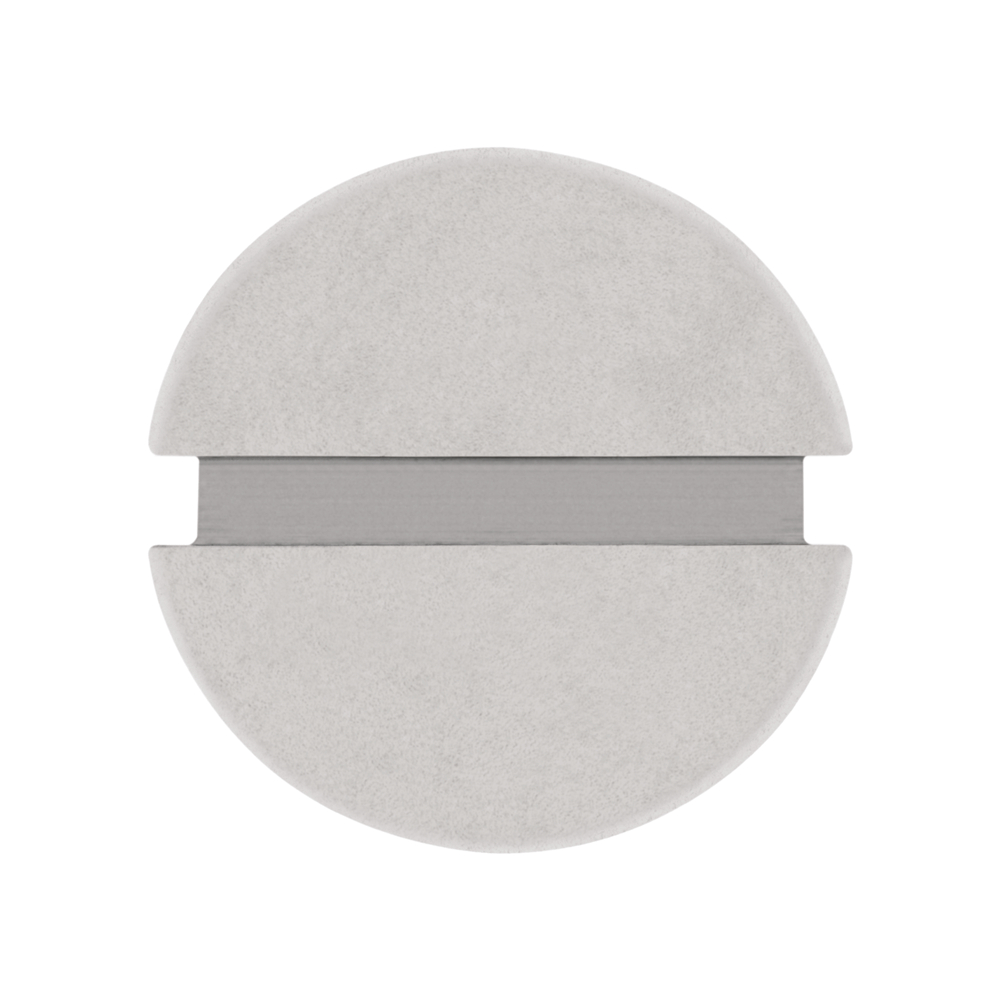

Slotted:

Shape: A simple slot in the screw head.

Advantages: Easy to manufacture and compatible with common screwdrivers.

Disadvantages: Low torque and prone to screwdriver slippage.

Common uses: Electronics, carpentry, DIY

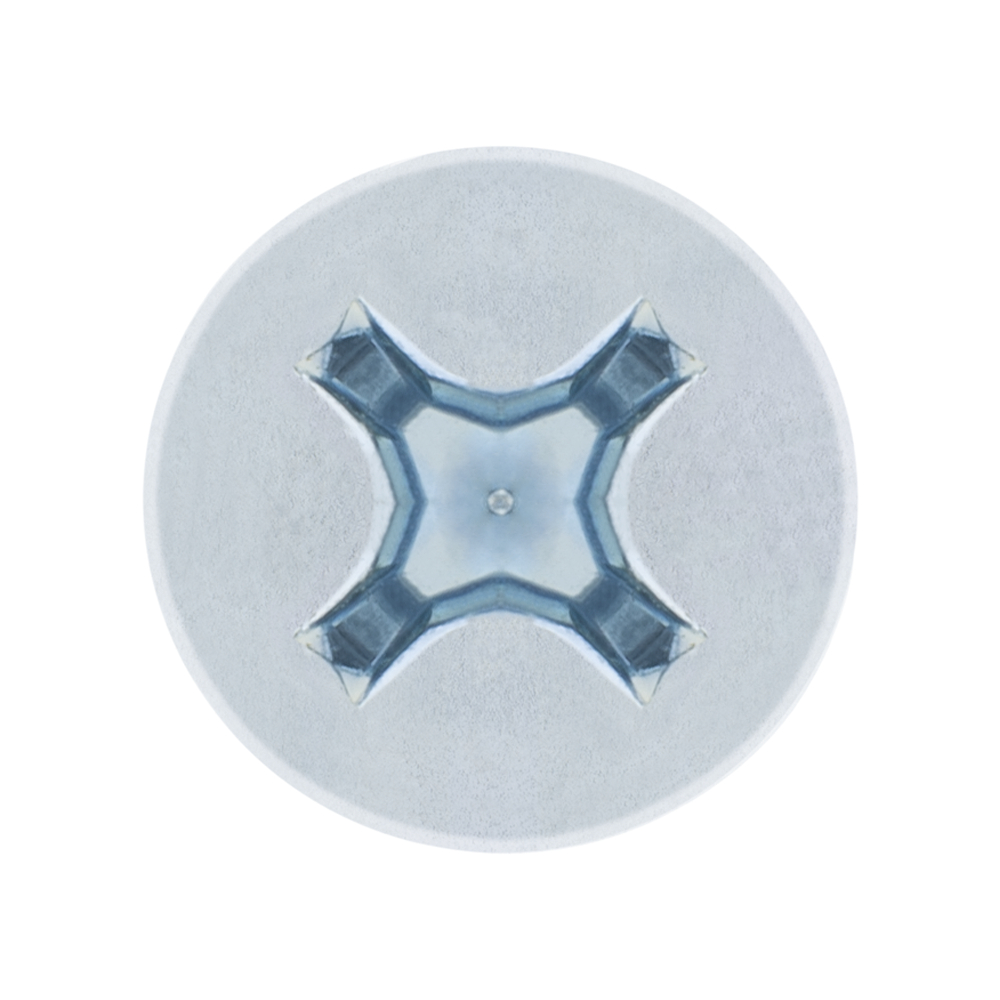

Phillips or cross-shaped:

Shape: Symmetrical cross on the head.

Advantages: Self-centering, prevents tool slippage.

Disadvantages: Can “cam out” under high torque.

Common uses: Electronics, automotive, household appliances.

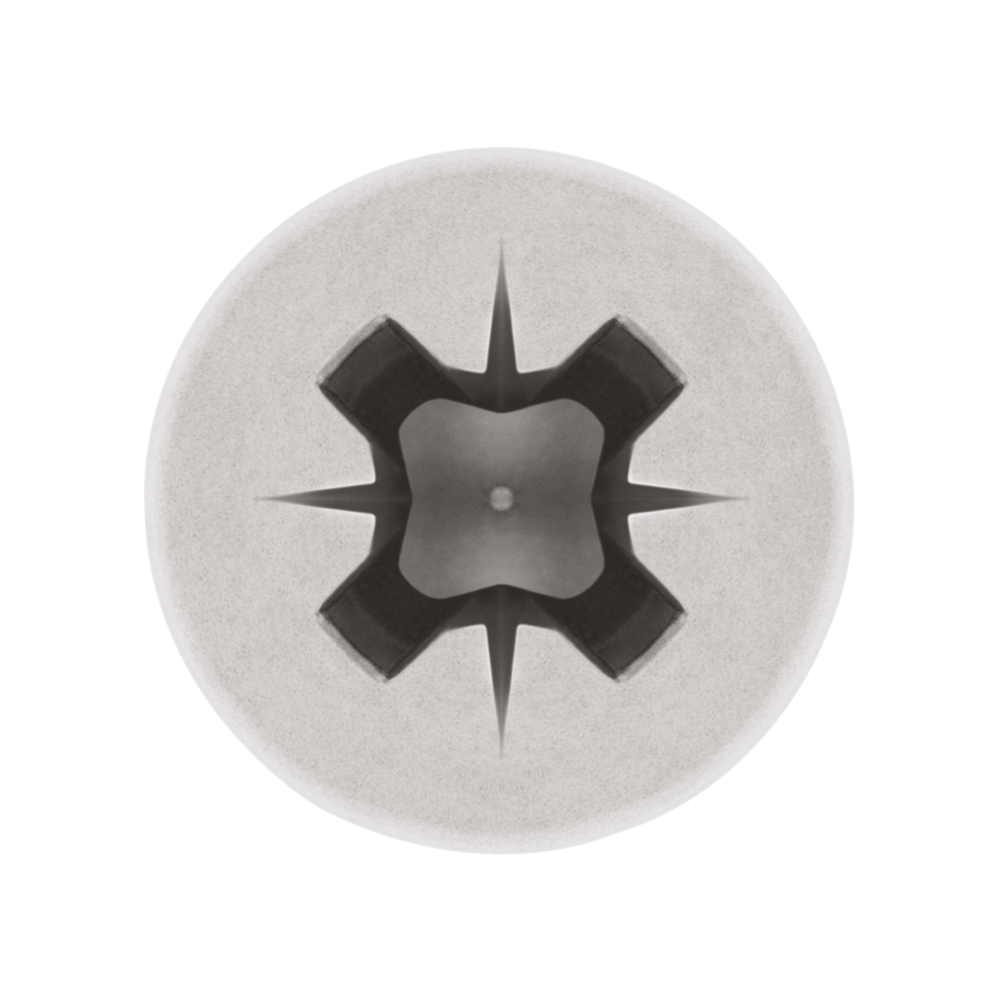

Pozidriv or improved cross-shaped:

Shape: Similar to Phillips but with additional ribs.

Advantages: Greater wear resistance and better torque transmission.

Disadvantages: Requires a specific screwdriver.

Common uses: Automotive, carpentry, machinery.

Robertson or square:

Shape: Square cavity in the screw head.

Advantages: High torque, less chance of damage.

Disadvantages: Less common outside North America.

Common uses: Construction, industrial carpentry.

Hexagonal or Allen:

Shape: Hexagonal recess in the head.

Advantages: High torque resistance and durability.

Disadvantages: Requires Allen wrenches, can accumulate dirt in the recess.

Common uses: Bicycles, furniture, industrial machinery.

Torx or hexalobular:

Shape: Six-pointed star.

Advantages: Increased contact between tool and screw, minimizes wear.

Disadvantages: Requires a Torx screwdriver.

Common uses: Automotive, electronics, heavy machinery.

Combined recesses

Shape: Combination of two types of drives in one head.

Advantages: Versatility in tightening tools.

Disadvantages: Less resistance in some cases.

Common uses: Household appliances, general hardware.

Key factors for choosing the right recess

When selecting a screw recess, it is important to consider:

Required torque level: Drives like Torx and Allen offer better resistance than slotted ones.

Material to be joined: Hardness and thickness influence the choice of recess. Metal screws may require better gripping drives, such as Pozidriv or hexagonal.

Available tools: Some drives require specialized tools (Allen, Torx).

Frequency of disassembly: For frequent use, a resistant recess like Torx or Robertson is recommended.

Security and protection: Some security screws include specialized drives to prevent unauthorized tampering.

Comparative table of screw recesses

RECESS TYPE | SHAPE | CHARACTERISTICS | APPLICATIONS |

Slotted | Straight | Economical and easy to use | DIY, carpentry |

Phillips | Cross | Self-centering, common | Automotive, appliances |

Pozidriv | Enhanced cross | Greater wear resistance | Construction, carpentry |

Robertson | Square | High torque, resistant | Industry, carpentry |

Hexagonal (Allen) | Inner hexagon | Resistant, ideal for machinery | Bicycles, furniture |

Torx | Six-pointed star | High torque, difficult to damage | Electronics, automotive |

Combined | Multiple designs in one head | Versatility | Hardware, appliances |

Choosing the correct screw recess is key to achieving a secure, efficient, and durable fastening. If you want to learn more about the different parts of a screw, check out this detailed article.

Each recess has its own advantages, so selecting the right one will depend on the type of application, material, and available tool.

At CHAVESBAO, we offer a wide range of fasteners adapted to different industries. If you need technical advice, do not hesitate to contact us via email at info@chavesbao.com, by calling 944 12 34 56, or visiting our website.