The DIN 912 socket screw, which is similar to the ISO 4762 standard, is the most widely used socket screw on the market due to its suitability for all types of applications in industry, machinery, automotive and construction, among others. Its internal hexagonal design, which requires an Allen key for tightening, makes it a versatile and resistant solution.

In this article, we will explore in detail the different types, characteristics and applications of this type of socket screw.

DIN 912 socket screw typology

The DIN 912 is a standard screw that is classified according to its mechanical strength and type of coating. Each classification offers specific characteristics that make it suitable for different applications.

DIN 912 8.8 BL: offers good tensile strength and is ideal for general applications. The black finish (BL) is an aesthetic solution to avoid painting and provide strength.

DIN 912 8.8 ZP: similar to the above, but with a zinc plated finish (ZP) which significantly improves its corrosion resistance, making it suitable for wet or outdoor environments.

DIN 912 10.9 BL: with a higher tensile strength than the 8.8, this bolt is ideal for applications requiring higher mechanical strength.

DIN 912 12.9 BL: the strongest of the series, offering excellent tensile and shear strength.

DIN 912 A2: this bolt is made of A2 stainless steel, making it highly corrosion resistant and suitable for applications in marine or chemical environments.

DIN 912 A4: similar to A2, but with a higher molybdenum content, giving it even greater resistance to corrosion, especially in aggressive environments.

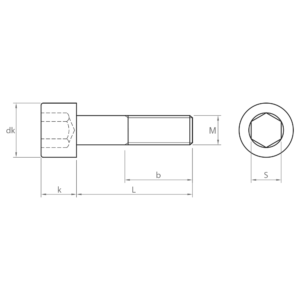

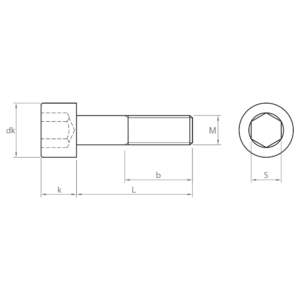

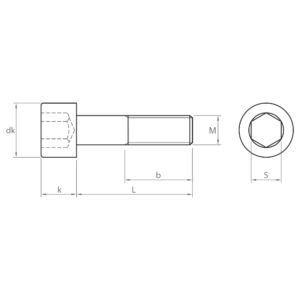

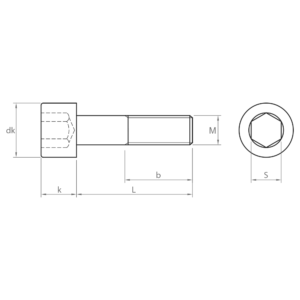

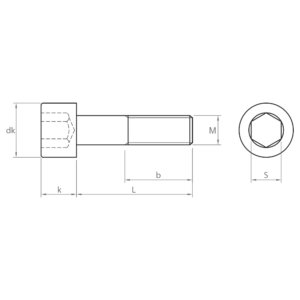

DIN 912 socket screw features

DIN 912 socket screws are characterised by:

- Cylindrical head with hexagon socket: facilitates tightening and untightening with an Allen key, especially when the application space is limited.

- Metric thread: available from metric 3 to 36, offering versatility for a wide variety of applications.

- High mechanical strength: 8.8, 10.9 and 12.9 grades offer excellent tensile strength.

- Corrosion resistance: zinc plated, black, A2 and A4 stainless steel coatings provide excellent corrosion protection.

DIN 912 socket screw applications

DIN 912 socket screws, thanks to the ease of tightening with the Allen key, are especially recommended for joints in tight or difficult to access spaces, but which require a strong tightening. They find applications in a wide range of sectors such as:

- Industry: manufacture or repair of industrial machinery and equipment.

- Automotive: manufacture and repair of automobiles, motorbikes and bicycles.

- Construction: fastening of metal elements and assembly of structures.

- Furniture: joining of metal components in furniture and structures.

- Electronics: fixing of electronic components on boards and casing.

- Naval sector: fastening of elements in boats and marine structures.

Due to its strength, ease of tightening and versatility, the DIN 912 allen screw is the most widely used allen screw on the market. Its wide range of finishes, qualities and metrics make it an ideal solution for a wide variety of industrial applications. At CHAVESBAO we have a wide range of socket screw solutions.

If you need advice on choosing the right bolt for your project, do not hesitate to contact us.