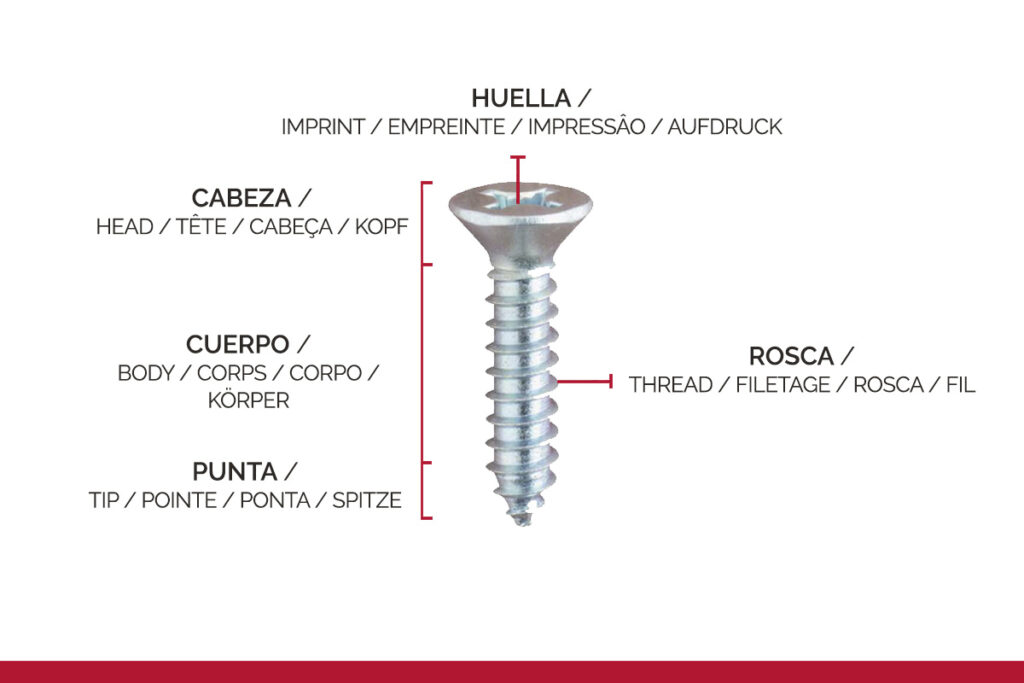

Have you ever wondered how a simple piece of metal such as a screw can securely join materials as diverse as wood, metal or plastic? The answer lies in its design, which combines different elements with specific functions.

In this article, we will explore in detail the parts of a screw and their importance in the world of fastening.

What is a screw?

A screw is a cylindrical fastener with a head and a helical thread.

It is used to join two or more parts securely by creating a mechanical link. It is composed of several parts that work together to achieve this goal. This article describes the main parts of a screw: head, recess, tip and thread.

Screws are used in a wide variety of applications, such as construction, industrial machinery and domestic DIY.

What types of screw exist

There are a wide variety of screws, each designed to fulfil a specific function. Some of the most common types include:

- Hexagonal screws: most commonly used in general applications, thanks to their versatility and ease of handling.

- Socket screws: with their internal hexagonal design, they are suitable for all types of applications.

- Self-tapping screws: they drill and fix the material at the same time, without the need for pre-drilling, such as the self-drilling screw DIN 7504-N.

- Wood screws: designed for fastening into wooden materials, they usually have a sharp point and a coarser thread. An example of this type of screw is the lag screw DIN 7505 A.

- Metal screws: with a finer thread and a stronger point, ideal for joining metal parts.

Screws are used in a wide range of sectors, such as construction, automotive, industry, electronics and furniture manufacturing. Their versatility makes them an essential part of any workshop or construction site.

Which are the parts of a screw?

Head

It is the upper part of the bolt that serves as a fulcrum for the tightening tool. There are different types of heads, such as hexagonal, flat, round and countersunk. The shape of the head determines the type of tool that will be used to tighten or loosen the bolt. There are numerous types of screw head, each with its own characteristics and applications. Some examples are:

- Round: hemispherical shape with a groove. It does not give resistance to the imprint and does not allow automatic assembly. It is currently out of use.

- Cylindrical: it allows all types of tracks. It is used in spaces where it is necessary that the head does not protrude.

- Rounded: it is an evolution of the round head and allows all types of prints.

- Low rounded: it has a larger bearing surface on the material to be fixed and avoids the installation of a flat washer. It is used in applications where a high effort is transmitted and soft materials such as plastic or methacrylate.

- Low flush with washer: it has a larger support surface on the material to be fixed and once inserted, it does not stand out much from the surface. It is usually used in white materials that cannot be countersunk.

- Hexagonal: allows the use of fixed spanners and magnetic sockets. It is used in metal carpentry.

- Hexagonal with washer: it has a larger support surface on the material to be fixed.

- Hexagonal with flange: it is equivalent to the hexagonal with large diameter reinforced washer. It has a better distribution on the material to be fixed.

- Countersunk: it is flush with the material to be fastened and, in resistant materials, it needs to be countersunk beforehand. Commonly used in wood.

- Tallow drop: similar to the countersunk, but allows for more depth of impression. It is used in metal fittings with pre-sinking.

- Clipping: special head for clipping decorative elements into PVC profiles. Used for jambs, shutter joints in PVC joinery.

- Flat: with bevelled edges, the cone under the head allows the screw to be centred in the sheet metal to be fastened. Used in applications where head thickness is critical, such as window frames.

- Extra-flat: minimum head thickness which conditions the housing of the recess. It is used in applications where countersinking is not possible and the head thickness is critical.

- Trumpet: radius below the head in the shape of a trumpet. Commonly used in the fixing of plasterboard.

- Countersunk with grooves: automatically countersinks the material to be fastened during screwing. Used in hardwood, melamine, etc.

Recess

This is the cavity in the head of the screw where the tip of the tool is inserted. The most common forms of recesses are cross-shaped, flat and Torx (star) recesses. The choice of the recess depends on the type of tool available and the required tightening force. As with the heads, there are several different types of footprint, each with its own advantages and disadvantages:

- Slotted: simple and universally usable, but with low tightening torque.

- Cruciform type H: low torque, self-centring, so no run-out. Used in assembly lines. The screwdriver can slip.

- Square (Robertson): easy insertion and high torque.

- Cruciform type Z (Pozidriv): the screwdriver does not slip out and medium torque is achieved.

- Hexagonal (socket): allows high torque, but is difficult to use in automatic systems.

- Hexalobular (Torx): ideal for automated uses, although it is not widely used.

- Combined: allows assembly with different tools, but the footprint tends to weaken.

Body

The body or shank is the cylindrical part of the screw that is inserted into the material to be fastened. The length of the shank is an important factor to consider when choosing a screw.

Point

It is the lower part of the screw that comes into contact with the material to be joined. The point can be sharp to facilitate insertion into hard materials, or flat for a larger bearing surface. Some screws have self-drilling points, allowing installation without the need for pre-drilling. There are different types of points, each designed for a specific type of material:

- Drill bit: for direct drilling of metal materials.

- Reduced drill bit: for drilling through thin metal materials.

- Type S (pin): special tip for penetrating soft or thin metals.

- Type C: requires pre-drilling.

- Type F: self-tapping for hard metals, requires pre-drilling.

- Diamond: 45º angle, sharp point and triangular faces, used in concrete.

- Guide: facilitates the guidance of the screw in the pre-drilled hole. Used in hard wood.

- 2-wing drill bit: for wood-metal joints, it opens a larger pre-drilled hole in the wood to prevent the drill bit from heating up and the wood from breaking or cracking.

- Harpoon: oval shape to allow the plastic plug to be driven through without damaging it. For nailable plugs.

Thread

It is the helical part of the screw that generates the clamping force when tightened. The thread can be metric (the most common) or Whitworth. The pitch of the thread (distance between two consecutive threads) determines the clamping force and the feed rate of the screw.

- External: on the external surface of a cylinder, as in screws.

- Internal: inside a part, as in nuts.

The choice of the right fastener for a given application depends on several factors, such as the type of material to be joined, the thickness of the parts, the required clamping force and the environmental conditions.

In short, every part of a fastener plays a crucial role in its function of securely joining parts. The head provides the fulcrum needed to apply the clamping force, the shank ensures proper tool holding, the tip facilitates penetration into the material and the thread generates the clamping force. By understanding the different parts and their variations, the right fastener can be selected for each application.