The head of a fastener is a fundamental part that determines its functionality, its application and the final finish of a joint. There are numerous types of heads, each designed to serve a specific purpose. In this article, we will explore the different types of screw head, their characteristics and applications, based on a visual and detailed classification.

Why is the head of a screw important?

The head of a screw serves several key functions:

- Bearing point: it serves as the point of application of force to tighten or loosen the screw.

- Aesthetics: it influences the final appearance of the joint, especially in visible applications.

- Protection: In some cases, the head may protect the thread or surrounding material.

- Tool compatibility: the imprint on the head determines the type of tool to be used.

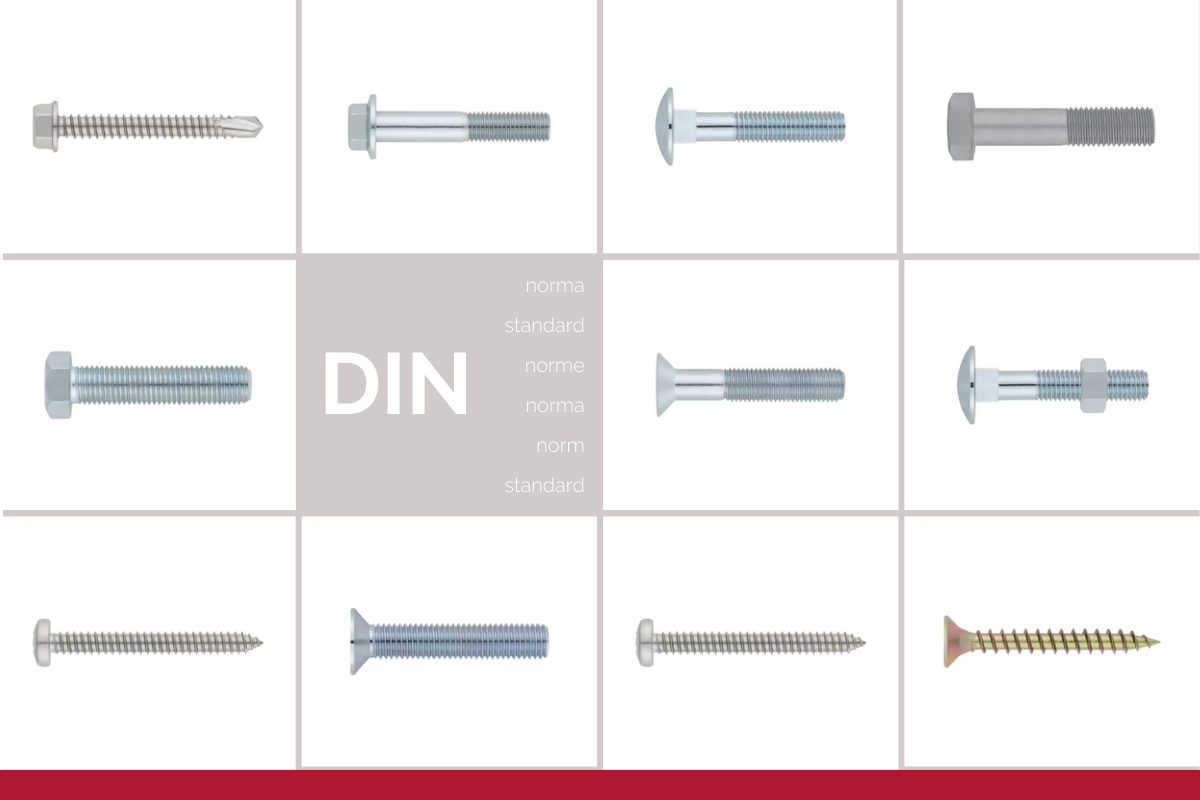

Types of screw heads

Screw heads can be classified according to their shape, function and material. Some of the most common ones are described below:

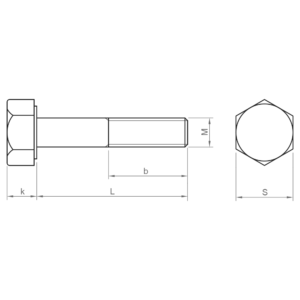

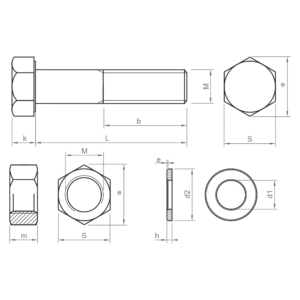

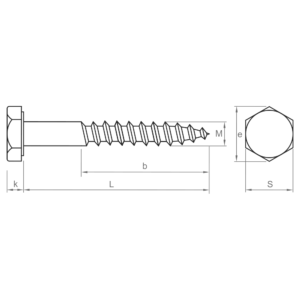

Hexagonal head

- Hexagonal screws are the most commonly used in general applications due to their versatility and ease of use.

- Allows a high tightening torque and is compatible with fixed spanners and sockets.

- Used in metal constructions, machinery and industrial applications.

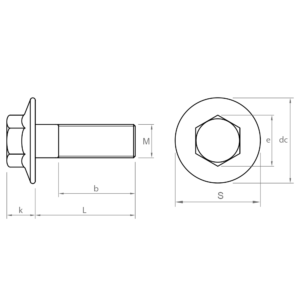

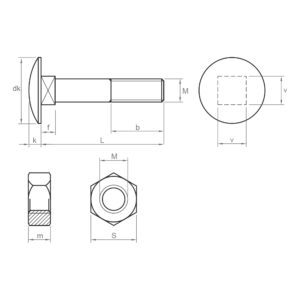

Hexagon head with washer

- Equivalent to the hexagonal screw with incorporated washer.

- A larger bearing surface is obtained on the material to be fastened.

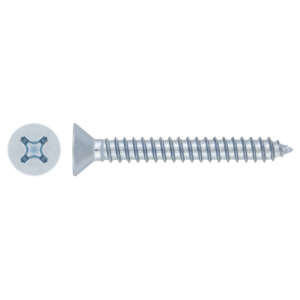

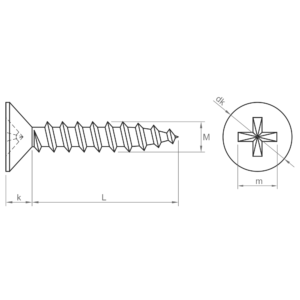

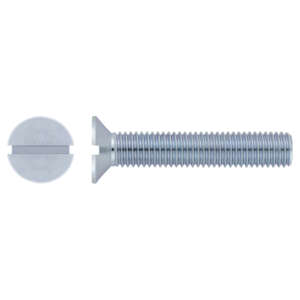

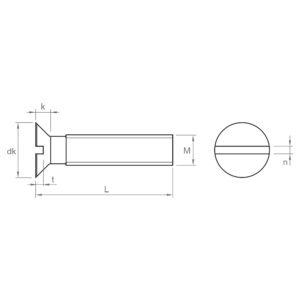

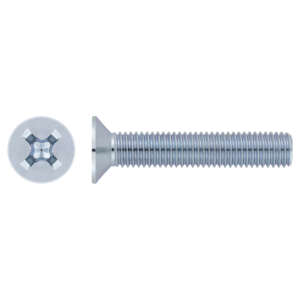

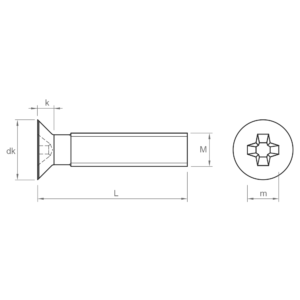

Flat head

- Also known as countersunk, it is flush with the surface when tightened, offering an aesthetic finish.

- Used in carpentry, joinery and any application where a smooth finish is required.

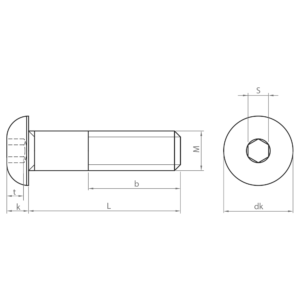

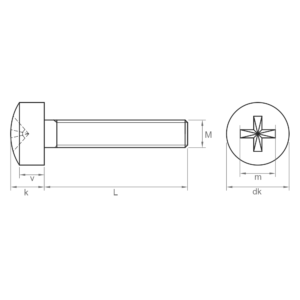

Round head

- Semi-spherical in shape and does not protrude from the surface.

- Used in applications where high torque is not required and a rounded finish is desired.

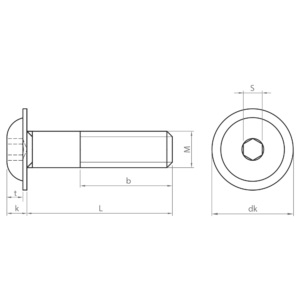

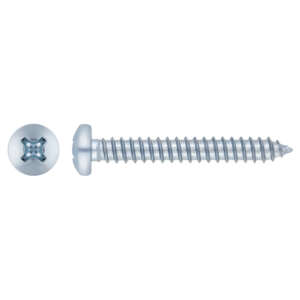

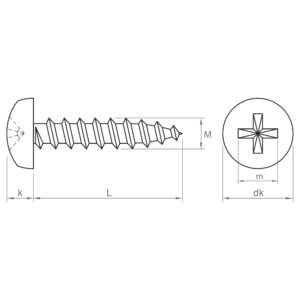

Panhead

- This is an evolution of the round head.

- Its application is general and allows all types of mortises.

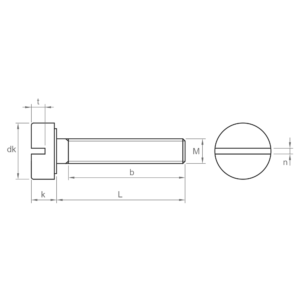

Cylindrical head

- Similar to the round head, but with a more cylindrical shape.

- Used in applications where a strong and durable head is required.

Safety head

- Has a special groove that requires a specific tool for tightening.

- Used in applications where it is desirable to prevent the bolt from being loosened easily.

Factors to consider when choosing a screw head:

- Material: what the material of the part to be joined is going to be.

- Material thickness: the depth of thread required.

- Tightening force required: the strength the joint must withstand.

- Final appearance: whether a smooth finish is required or whether the head will be visible.

- Available tools: the type of tool to be used to tighten the bolt.

The choice of fastener head is critical to ensure a secure and durable fastening. Each type of head has its own characteristics and applications, so it is important to select the right one according to the specific needs of each project.

Do you need more information? You can contact our technical service at info@chavesbao.com, through our website or by calling us on (+34) 944 12 34 56.